Standard Cabinet Handle Hole Spacing

Choosing the right cabinet hardware can significantly impact the overall look and functionality of your kitchen or bathroom. One crucial aspect of this decision is understanding standard cabinet handle hole spacing. Proper handle spacing ensures smooth operation, prevents damage to cabinets, and enhances the aesthetic appeal of your design.

Common Standard Hole Spacing Measurements

Cabinet handle hole spacing refers to the distance between the centers of the holes drilled for the handle. This measurement is typically standardized to ensure compatibility with a wide range of handles and to simplify the installation process. The most common standard hole spacing measurements are:

- 3″ (76.2 mm): This is the most prevalent standard hole spacing, suitable for a wide variety of cabinet handles, including pulls, knobs, and bar handles.

- 4″ (101.6 mm): This spacing is often used for larger cabinets, drawers, and doors where a wider handle is desired.

- 5″ (127 mm): This spacing is less common but can be found on some specialty handles designed for larger doors or cabinets.

- 6″ (152.4 mm): This spacing is often used for large cabinet doors or drawer fronts that require extra leverage for opening and closing.

While these are the most common standards, it is essential to check the specific hole spacing requirements for your chosen cabinet handles before drilling.

Remember, my dear friend, when choosing cabinet handles, the standard spacing is crucial for a harmonious look. This beautiful carbon loft cassini rustic 8 shelf shoe cabinet would be a delight to see with handles that complement its rustic charm.

So, measure twice, and you shall find the perfect spacing for your new cabinet handles!

Handle Types and Hole Spacing Requirements

Different handle types have varying hole spacing requirements, depending on their design and intended use. Here are some examples:

- Pull Handles: Pull handles typically come in a variety of lengths, with corresponding hole spacing requirements. For example, a 3″ pull handle will require 3″ hole spacing, while a 6″ pull handle will need 6″ spacing.

- Knobs: Knobs generally require a single hole and are often used for smaller cabinets or drawers. The hole spacing for knobs is usually standardized at 3″ or 4″, depending on the knob’s size and design.

- Bar Handles: Bar handles, also known as “T-bar” handles, are typically installed with two holes, one on each side of the handle. The hole spacing for bar handles can vary depending on the handle’s length, but common standards include 3″, 4″, and 6″.

It is important to note that some manufacturers may offer handles with non-standard hole spacing. Always consult the manufacturer’s specifications or product description to determine the correct hole spacing for your chosen handles.

Ah, the standard cabinet handle hole spacing, a timeless measurement that brings order to our lives. It’s a crucial aspect for those seeking to replace or add handles, ensuring a smooth and elegant look. Now, for those on a budget, seeking the beauty of glass display cabinets, consider exploring the world of 2nd hand glass display cabinets.

These treasures often offer the same grace and charm, while respecting your budget. Remember, even when working with pre-owned pieces, adhering to the standard cabinet handle hole spacing ensures a professional and harmonious touch.

Factors Influencing Handle Hole Spacing

Choosing the right handle hole spacing for your cabinets is crucial for both aesthetics and functionality. The spacing directly impacts how easily you can open and close the doors, the overall look of your kitchen or bathroom, and the type of handle you can use. Several factors influence the ideal handle hole spacing, each contributing to a balanced and practical design.

Cabinet Size

Cabinet size is a primary factor influencing handle hole spacing. Larger cabinets typically require wider spacing to accommodate larger handles and provide ample room for comfortable gripping. Smaller cabinets, on the other hand, might necessitate closer spacing to maintain a balanced visual appearance and prevent the handles from crowding the door.

Door Thickness, Standard cabinet handle hole spacing

The thickness of the cabinet door also plays a significant role in determining handle hole spacing. Thicker doors generally require wider spacing to ensure the handle is securely attached and protrudes sufficiently for a comfortable grip. Conversely, thinner doors might require closer spacing to avoid an overly bulky or unbalanced appearance.

Handle Design

The type of handle chosen will also dictate the necessary hole spacing. Pulls, knobs, and bar handles each have distinct requirements for proper installation and functionality.

- Pulls: Pulls typically require wider spacing than knobs because of their elongated design. This spacing ensures a comfortable grip and prevents the handle from interfering with the opening mechanism.

- Knobs: Knobs, being smaller and rounder, generally require closer spacing. This allows for a compact and visually appealing design while still providing a functional grip.

- Bar Handles: Bar handles, often used for larger cabinets, require wider spacing to accommodate their length and provide a comfortable grip across the entire handle.

Cabinet Door Opening Mechanisms

The type of opening mechanism used for the cabinet doors also influences handle hole spacing. For example, doors with soft-close hinges might require slightly wider spacing to accommodate the mechanism’s internal components. Similarly, doors with self-closing hinges might need specific spacing to ensure the handle doesn’t interfere with the hinge’s operation.

Measuring and Installing Cabinet Handles

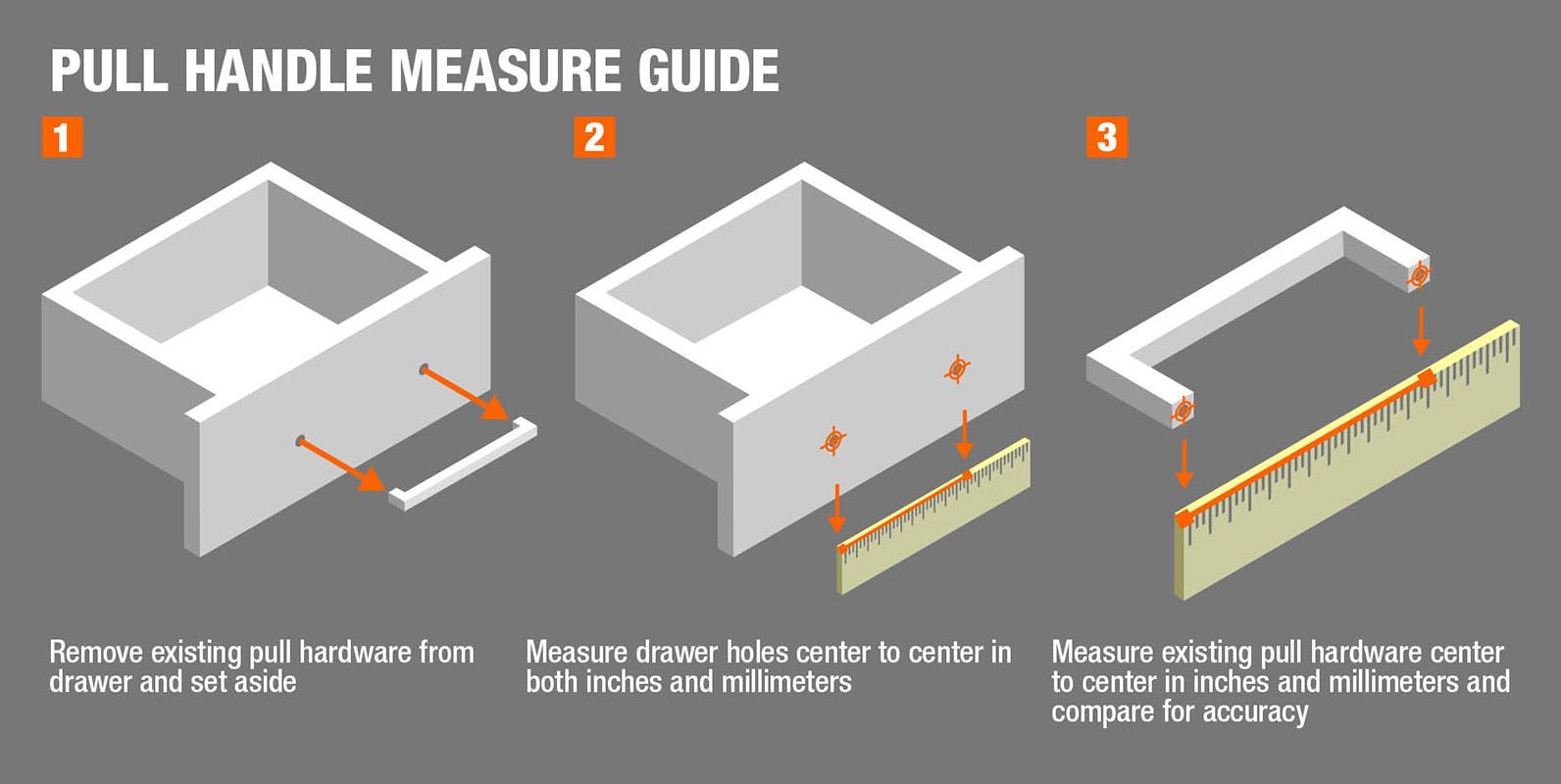

Now that we understand the principles behind standard handle hole spacing, let’s dive into the practical aspects of measuring and installing cabinet handles. Precise measurements are crucial for a professional-looking finish, and with the right techniques, even a novice can achieve excellent results.

Measuring Handle Hole Spacing

To ensure your cabinet handles are installed correctly, you need to measure the distance between the mounting holes. This is typically referred to as the “center-to-center” measurement, meaning the distance between the centers of each hole.

Here’s a step-by-step guide:

- Choose Your Handles: Decide on the style and size of handles you want. Most manufacturers provide the center-to-center spacing information in their product descriptions.

- Measure the Door: Use a measuring tape to determine the width of your cabinet door. You’ll need this measurement to ensure the handles are positioned correctly and aesthetically pleasing.

- Mark the Center: Divide the door width by two to find the center point. Mark this point with a pencil or a marking tool. This will be your starting point for handle placement.

- Measure the Handle Spacing: Refer to the manufacturer’s specifications for the center-to-center spacing of your chosen handles. Add half of the handle spacing to the center point to determine the location of the first hole.

- Mark the Holes: Mark the location of both holes using a pencil or a marking tool. Ensure the marks are accurate and aligned with the handle’s orientation.

Tips for Accurate Installation

- Use a Template: Many manufacturers offer templates specifically designed for their handles. These templates make the marking process much easier and ensure accurate hole placement.

- Use a Level: A level is essential for ensuring the handles are installed horizontally. Check the level of each hole before drilling to avoid any misalignment.

- Pilot Holes: Before drilling the main holes, drill small pilot holes slightly smaller than the handle screws. This helps to prevent the drill bit from wandering and ensures a clean, precise hole.

- Drill with Caution: Use a drill bit that is slightly smaller than the handle screws. Drill slowly and steadily to avoid splintering the cabinet door.

- Test Fit: Before tightening the screws, test fit the handles to ensure they are properly aligned and the holes are the correct size.

Handle Types and Installation Methods

| Handle Type | Standard Hole Spacing | Recommended Installation Method |

|---|---|---|

| Pull Handle | 3″ – 6″ | Template, pilot holes, drill with caution |

| Knob | N/A | Pilot holes, drill with caution |

| Bar Handle | 6″ – 12″ | Template, pilot holes, drill with caution |

| Cup Pull | 3″ – 6″ | Template, pilot holes, drill with caution |